Remanufacturing Explained

Remanufacturing, also called ‘reman’, is a branch in the aftermarket industry. A remanufactured product is defined as:

"A remanufactured part fulfils a similar function as the original part. It is restored from an existing part (core) using standardised industrial processes in line with specific technical specifications. A remanufactured part is given the same warranty as a new part, and it clearly identifies the part as a remanufactured part and states the remanufacturer."*

*This is the common definition from APRA (Automotive Parts Remanufacturers Association in USA, Europe and Asia), CLEPA (European Association of Automotive Suppliers), FIRM (International Federation of Engine Remanufacturers and Rebuilders, Europe), supported by MERA (Motor and Equipment Remanufacturers Association, USA) and RIC (Remanufacturing Industries Council, USA).

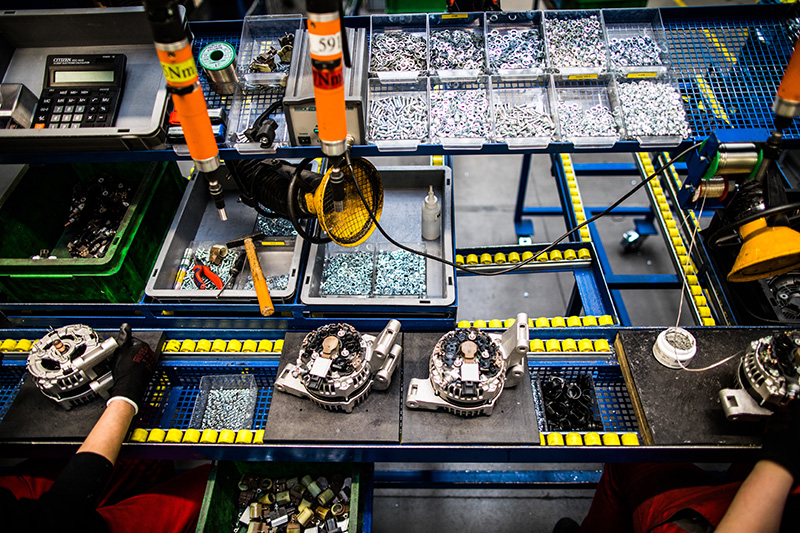

In other words, remanufacturing automotive parts means renovating used parts or components to OE-matching condition.